Plastic Sheet Production Line

SPC Floor Production Line – Visual Highlights

Eco-Friendly Material Processing

Image Example: Raw material mixing (stone powder, PVC resin, stabilizers).

Key Points: Formaldehyde-free, 100% recyclable, CARB/REACH compliance.

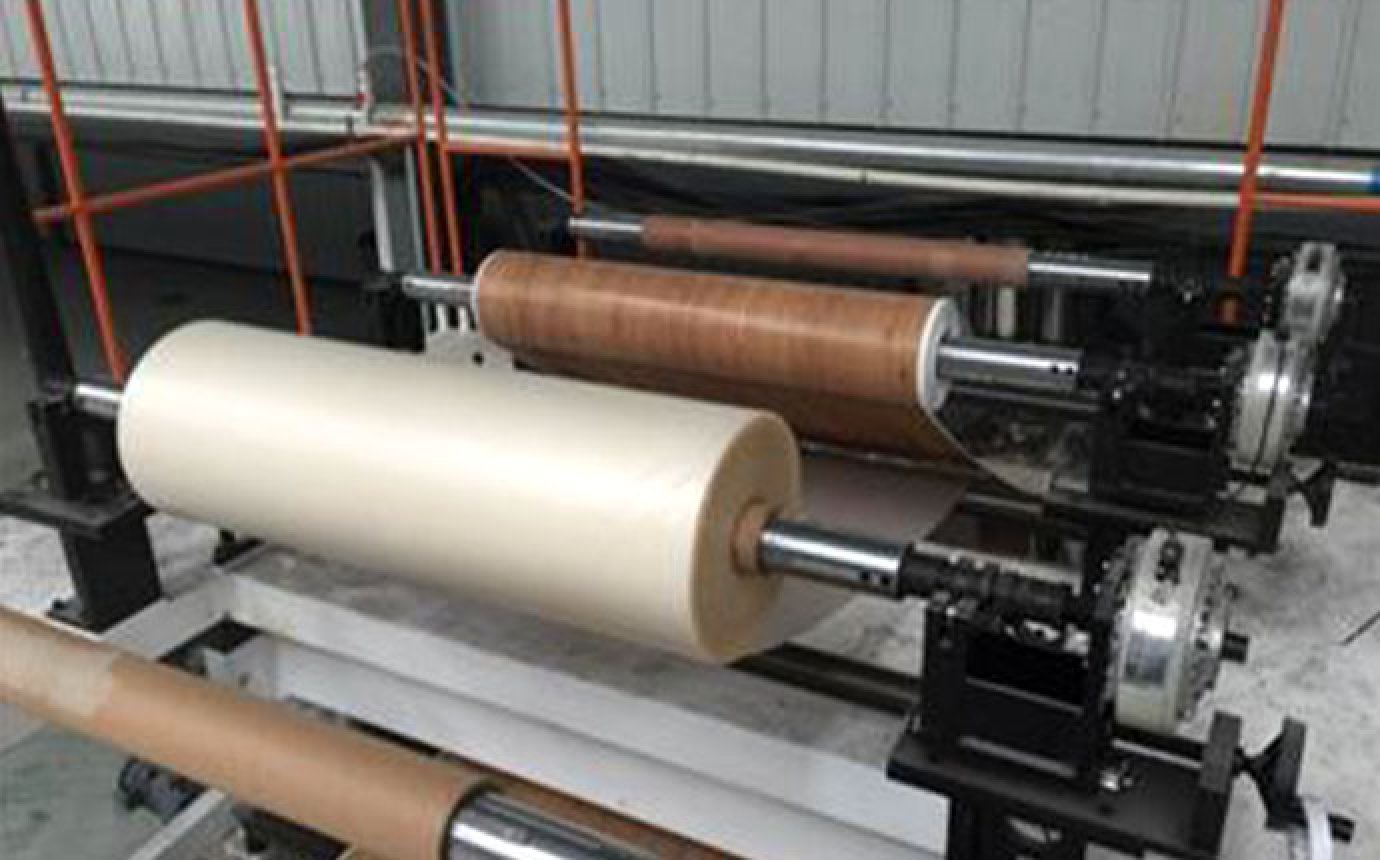

Advanced Core Equipment

High-Speed Mixing System: Precision material handling with automated controls

UV Coating & Embossing: Realistic wood/stone textures via synchronized thermal pressing

Smart Manufacturing Flow

Rapid Cooling: Multi-stage water cooling for dimensional stability

Automated Cutting & Stacking: Laser-guided cutting + robotic palletizing

AI Quality Control: Real-time defect detection with HD cameras

Product Versatility

Image Example: Finished SPC floors in wood, stone, and modern designs.

Applications: Waterproof, slip-resistant, and noise-reducing for homes, offices, hospitals.

Inquire Now

Add to Inquiry Basket

110/220 SPC石塑地板生产线 110/220 SPC stone plastic floor production line

项目概况project overview

1. Main raw materials: PVC powder, calcium powder, processing AIDS, color film, wear-resistant layer, UV paint, IXPE, etc.

2. Total power: 800KW, about 50% of actual operation.

3. Production output:

750-950kg/h (SJSZ-110 extruder - 40 tons /24 hours), 4.0mm floor 4300-4800 flat (24 hours)

4. Air pressure of air compressor: 0.6Mpa

5. At least 80 cubic meters of water are required for equipment recycling.

6. Production process: Raw materials (PVC resin, calcium powder and processing AIDS) mixing → extrusion →UV → multi-slice sawing → unlocking → mute pad → packaging

7. Production area: more than 5000 square meters, length can not be less than 60 meters, height can not be less than 7 meters.

Main raw materials: PVC powder, calcium powder, processing AIDS, color film, wear-resistant layer, UV paint, IXPE, etc.

2. Total power: 800KW, about 50% of actual operation.

3. Production output:

750-950kg/h (SJSZ-110 extruder - 40 tons /24 hours), 4.0mm floor 4300-4800 flat (24 hours)

4. Air pressure of air compressor: 0.6Mpa

5. At least 80 cubic meters of water are required for equipment recycling.

6. Production process: Raw materials (PVC resin, calcium powder and processing AIDS) mixing → extrusion →UV → multi-slice sawing → unlocking → mute pad → packaging

7. Production area: more than 5000 square meters, length can not be less than 60 meters, height can not be less than 7 meters.

Media Contact: https://www.hst-plasticmachinery.com

Name:Nancy Bao

Company Name:Qingdao Haosaite Plastic Machinery

whatsapp/Phone Number/Wechat:+8615854298193

Email Address:suji@haosaite.com

Sales6@haosaite.com

Website:Qingdao Haosaite Plastic Machinery

Arress:NO.398 B-9,Jiaozhou Road Jiaozhou Qingdao City,China